by Richard Keech

2019-04-27

I’ve heard a few people say that covering IC-rated LED lights is bound to cause accelerated failure rate. One the one hand it’s well known that electronic devices fail more quickly when they get too hot. On the other hand, you’d think that the manufacturers of IC-rated lights would not rate them as OK to cover if it would cause significant reduction in their likely service life. So I thought I’d delve a little closer.

Background

In an earlier post I wrote about the importance of replacing downlight fittings, not just the bulbs. One of the aspects covered in that post was how, with modern IC-rated lights, it is now safe and legal to cover the lights with appropriate insulation. Compared with the normal practice of leaving a radius of at least 100mm around the light clear of insulation, covering the lights allows for greatly improved insulation.

Concerns

A couple of people responded with the view that covering downlights, IC-rating or not, is careless and likely to lead to greatly shortened service life in practice. I thought I’d explore this with a little experiment.

Electronics and temperature

It’s well understood that at elevated temperatures, electronic circuits will fail more quicky. Temperature is usually considered non-problematic until about 70C.

According to TWI “Conventional electronic components are designed to operate over a specified temperature range with upper limits generally set at 70°C for commercial applications, 85°C for industrial applications, and 125°C for military applications.”

Method

I have a good IC-rated downlight, some insulation, and a thermal imaging camera. My approach is to see how hot the unit gets with, and without insulation over the top.

Hypothesis. My hypothesis going into the experiment was that, for a good-quality light fitting, the temperature increase associated with covering the unit would be real but moderate, and that the implications for device reliability would be benign.

Materials and setup

Downlight. I’m using an Osram 8W unit purchase from Reduction Revolution here. They retail for $12.95. These units are interesting in that they do not have a separate power supply (regulator) unit. The regulator is built in to the top section of the body of the fitting.

Insulation. I covered the light with Autex Greenstuff polyester insulation material that is certified non-combustible and safe to use with IC-rated lights. The section of insulation was 100mm thick.

Measurements. I used a Cat S60 Android phone with built-in FLIR thermal imaging system. Measurements were taken assuming high-emissivity surfaces.

Situation. The light was placed on a carpeted floor and turned on. There was no incident sunlight. The room was unheated. Measurements were taken mainly on the upper body section housing the power supply (regulator) unit. The reported temperature readings are of this upper section unless stated otherwise.

Results

Initial conditions. Prior to turning on the unit it was at room ambient temperature, measured at 18.1C. Samples were take commencing about 30s after turning the light on with no insulation covering.

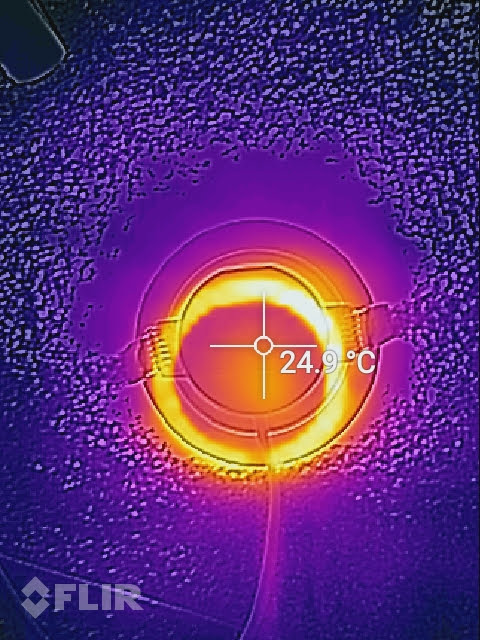

T plus 1 minute. The temperature came up quickly to 24.5C shortly after turn on.

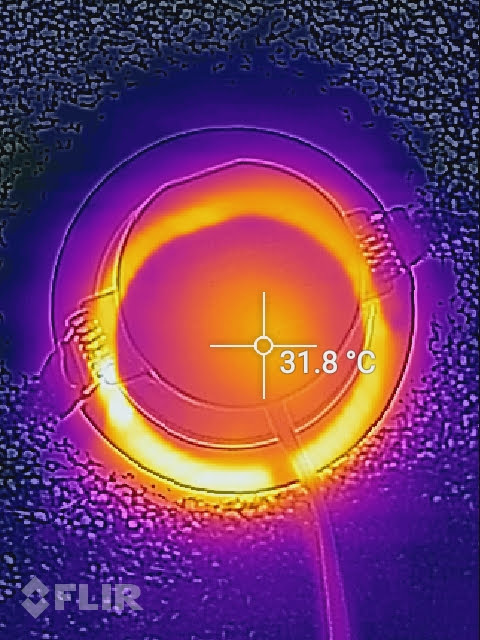

T plus ~10 minutes. The temperature stabilised and was measured at 31.8C.

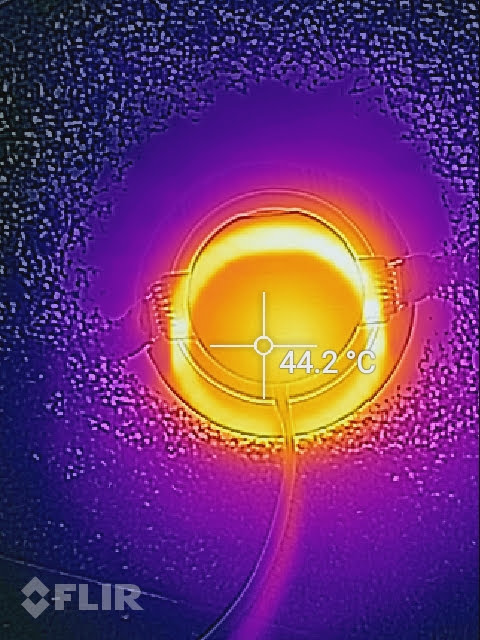

Then the insulation was place over the light.

T plus ~20 minutes. The temperature stabilised and was measured at 44.2C.

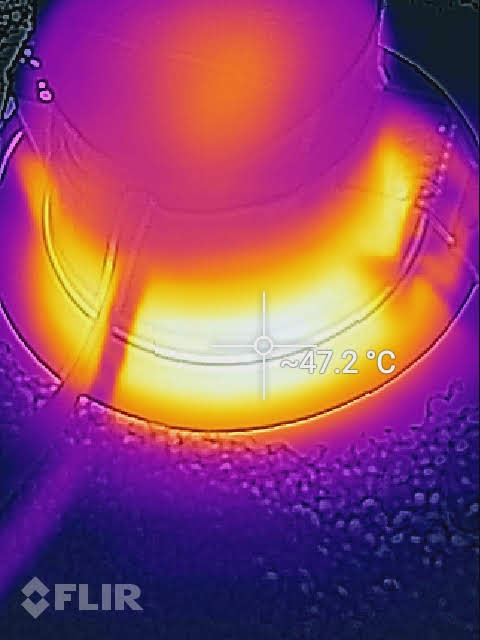

Other observations. The hottest section of the fitting was around the lower section near where the flange meets the conical section. At about T plus 15 minutes this was measured at 47C.

Analysis

The temperature of the uncovered unit stabilised at ~32C, and the covered unit at ~44C, so in the test conditions the insulation added about 12C to the temperature of the unit.

The rudimentary test situation involved the unit on a carpeted floor where the light flux was observed to directly heat the carpet, whereas in-ceiling installations would allow the light flux to dissipate more readily in the room below. So the measured temperatures in this case might be slightly elevated as a result. This factor would seem to make the conclusions err on the conservative side. On the other hand, the temperatures measured on the surface of the unit will be less than the temperature of the components embedded within.

Both the covered and uncovered temperatures are very moderate, and would seem to be comfortably under the 70C threshold temperature for concern, even allowing for the fact that the electronic components will have an elevated temperature relative to the body of the light fitting.

In real-world deployments in ceiling spaces in summertime conditions it can be reasonably expected that in-roof ambient temperatures often reach over 50C, and temperatures over 60C would not be unusual.

In this case, covering the unit with insulation would protect it from high ambient temperatures experienced in a ceiling cavity in hot summer conditions. So it’s plausible that in such conditions, covering the fitting with insulation might actually be reducing its temperature, relative to what it might reach when exposed to the elevated ceiling temperature situation.

Conclusions

The initial hypothesis was that this IC-rated light would not reach problematic elevated temperatures when covered with insulation. My results support that original hypothesis.

I conclude that covering this type of downlight unit with insulation is likely to be not problematic from a point of view of shortening the service life.

Further work

It would be interesting to measure temperatures of the unit in a ceiling in summertime, with and without insulation over the top. The findings here suggest a hypothesis that keeping the downlight fitting entirely within the thermal envelope, by covering it, could actually be beneficial by reducing the summertime extremes of temperature that the unit gets exposed to.