by Richard Keech

2018-10-10

The problem

Downlight fittings that you commonly see in Australian homes are often an energy and comfort nightmare. They can be associated with up to five different problems. Before you go replacing a halogen bulb with an LED replacement, read this.

Lighting efficiency

Legacy downlights often have halogen bulbs which use a lot of power for a given amount of light. Powers of 30 watts to 50 watts per fitting is common. This is about five times more energy than a good LED light producing equivalent light. This problem is frequently dealt with by replacing the existing halogen bulb with an LED bulb in the same fitting. This is good for the lighting efficiency, but does not improve the situation with the other related problems below.

Fire safety

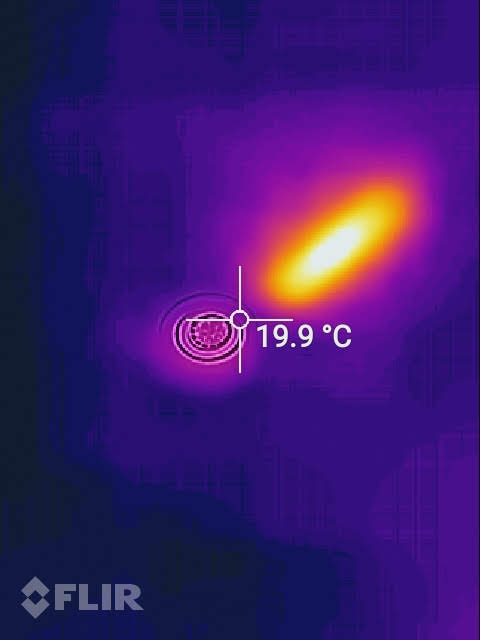

Legacy halogen downlights sometimes cause house fires because they get hot. The rules for the installation of these lights is supposed to eliminate that risk. As the picture below shows, that doesn’t necessarily stop the hot lights coming into contact with potentially flammable material.

Draughts

Many downlight fittings, and some bulbs are deliberately ventilated. So many fittings, in aggregate, amount to substantial pathways for uncontrolled airflow between inside and the ceiling space. Sometimes an unventilated halogen bulb is replaced with a ventilated LED bulb in the same fitting. This, perversely, reduces one aspect of efficiency (draughts) at the same time as another (lighting efficiency) is improved.

Insulation

Correct fitting of most downlight fittings involves leaving a considerable gap in the insulation around the fitting to help reduce fire risk. In so doing the level of effective insulation is seriously reduced – more so than you would expect. Correct fitting of insulation is supposed to allow for this effect. However it’s very common to see inadequate levels of insulation because of downlights.

As an example, if a home has R5.0 ceiling batts, but has 5% of the ceiling uncovered around downlights (ie insulation missing in 5% of the area) then the net effective insulation is only R2.5. Downlights are not the only thing that reduces insulation effectiveness. Builders are supposed to allow for this and add more insulation as required to achieve the design performance level.

Note that LED downlights cannot be covered with insulation unless it’s an LED fitting that specifically allows for it.

Power supply

Older halogen downlights are often served by an iron-core transformer. More modern downlights (halogen or LED) use smaller, lighter electronic transformers. Sometimes LED bulbs are put in place of halogen bulbs without replacing legacy transformers. These older transformers are quite inefficient and warm up.

The solution

If you have legacy halogen downlights then do not replace the bulbs with LED bulbs because of the significant lost opportunity that bulb replacement entails. In other words, replacing the bulb only fixes a small part of the total problem.

The recommended approach is to replace the entire fitting with a new LED-only fitting. These are sealed units and have no replaceable bulb. They come with a matching, or in-built transformer, and don’t cost much more than a replacement bulb.

Be sure to choose one that is rated as safe and legal to cover with insulation. Not all units are safe to cover. The light fitting pictured below is an example of one that is recommended. This fixes all the problems of a typical legacy halogen bulb and can safely be covered with insulation. These are available from here for only $12.95 at the time of writing.