This outlines a possibly novel approach to improve the efficiency and effectiveness of heat pumps used for home heating, cooling and hot water. This involves placing the units in the sub-floor space to exploit the thermal mass of the ground in both summer and winter.

By Richard Keech

2018-10-02

Heat pumps – background

(Skip this section if you already know the basics of heat pump operation.)

Heat-pump efficiency. Heat pumps are an amazing technology for both heating and cooling. They allow us to flexibly extract renewable ambient heat energy from a source medium, say the outside air in winter, and transfer it somewhere else, say the inside of our home. However the colder the source medium, the lower the efficiency of heat pumps for heating. Likewise, in summer, cooling efficiency lessens as the ambient temperature increases.

Air-source heat pumps. The source-medium for the heat defines the type of heat pump. Most heat-pumps we commonly see use the air as the source of the heat energy when heating, so we call them air-source heat-pumps.

Ground-source heat pumps. Much less common are heat-pump systems which have pipes laid under the ground. These systems heat and/or cool by exchanging heat energy directly with the ground. They can take advantage of the fact that the deep ground temperature is more stable, so the reductions in efficiency when the weather is really hot or really cold is much less. However the ground-source heat pumps have a much higher capital cost because of the ground works involved. Often this means that the marginal increase in efficiency is not sufficient to justify the increased cost.

Earth tubes for thermal mass

Earth tubes. An uncommon but well-understood way to use the thermal mass of the earth is to pass air through large heavy pipes or chambers under the ground. This can moderate the incoming air temperature in either summer or winter. The flow of air can be controlled by simple means which might need a fan, or could use passive means.

Controllable thermal mass. The fact that the air passing through the tubes can be controlled makes this very interesting compared to conventional approaches to thermal mass such as using a concrete slab on the ground (CSoG). CSoG construction is very common, and usually gives thermal mass that is tightly bound to the ground temperature in a way that is always present, ie it’s not controllable. So the appeal of earth tubes is they potentially give a thermal mass effect that can be turned off or on by controlling the movement of air.

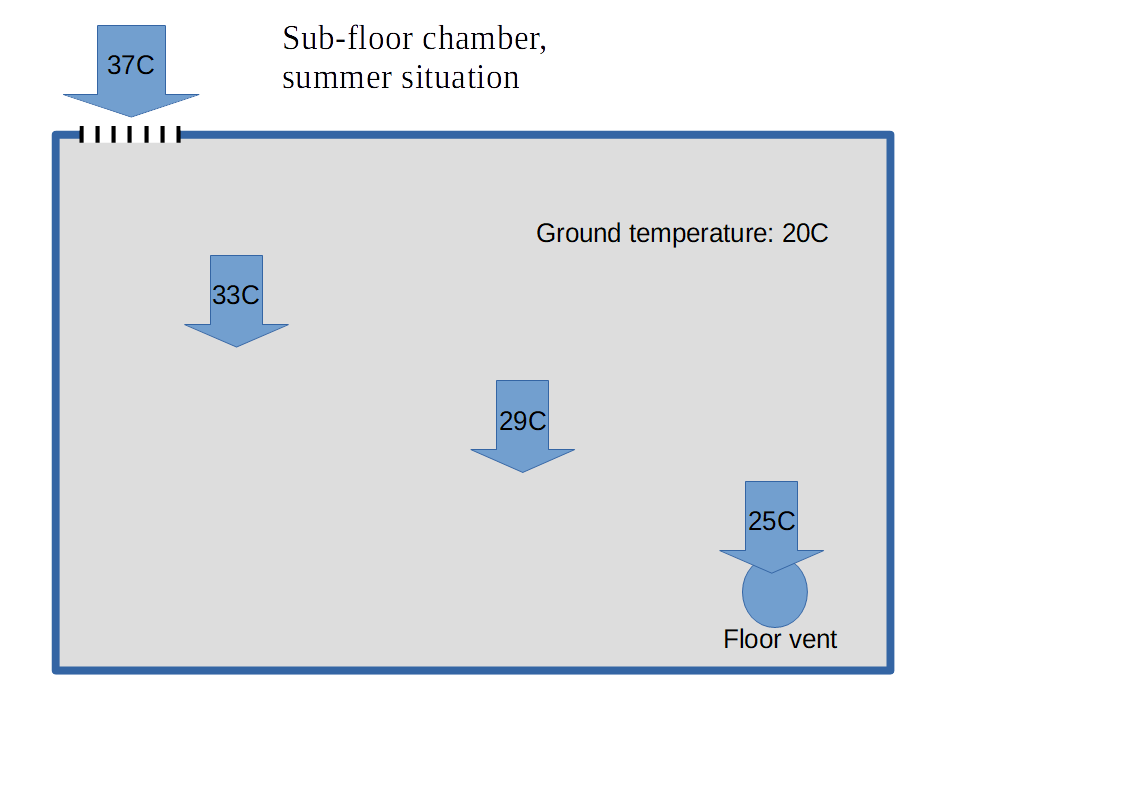

Cooling vs heating. For summer cooling in temperate climates earth tubes can potentially deliver air that’s sufficiently cool without needing a heat pump. In winter in a temperate climate, earth tubes are able to moderate the air temperature, but very unlikely to deliver air that’s sufficiently warm to be directly useful.

Downside. The downside of an earth tube is the up-front cost associated with the design, excavation and pipes. An earth-tube system that’s large enough to be useful is going to be quite costly.

Earth-improved heat-pump operation

Earth tubes + heat-pumps. A conventional air-source heat pump could conceivably be used in conjunction with something like earth tubes to benefit from moderated air temperature into the heat pump which would increase its efficiency. This could give a benefit in both summer and winter. However, a configuration of earth tubes with heat pumps would need to be bespoke and would not be cheap.

Sub-floor chambers. Some houses have, or could be built with, a raised floor which creates a sub-floor cavity or chamber that has a large exposed area of ground at a stable temperature. If air could be channelled through a sub-floor cavity in the right way, then it could work much like an earth tube. Conceivably this could have the advantage that it takes advantage of a situation (ie raised floor) that might already exist, and in so doing avoids the cost and work of a dedicated installation of earth tubes.

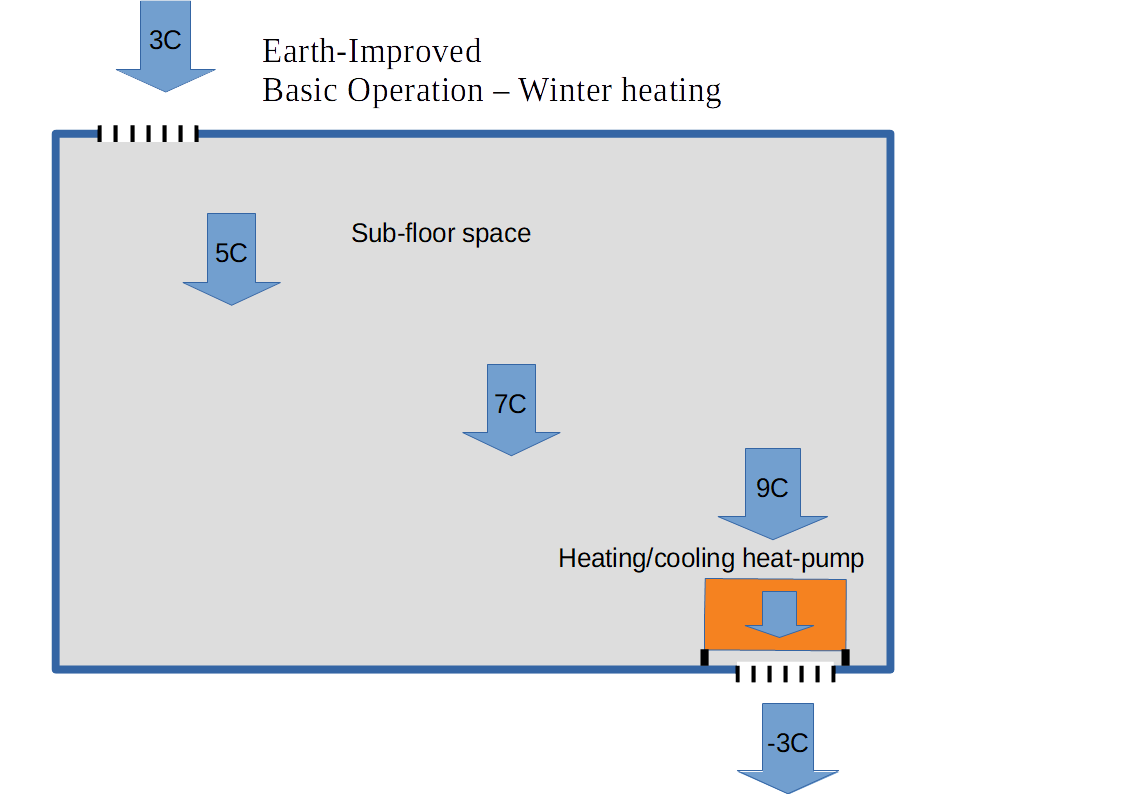

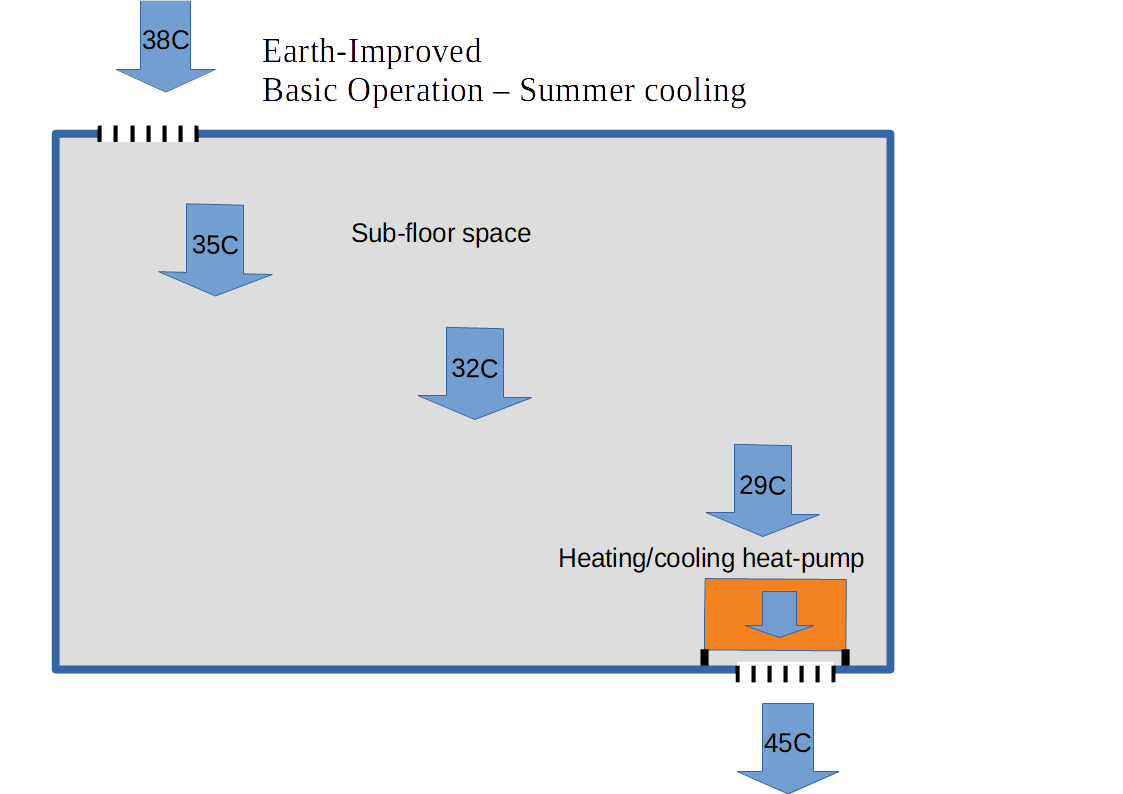

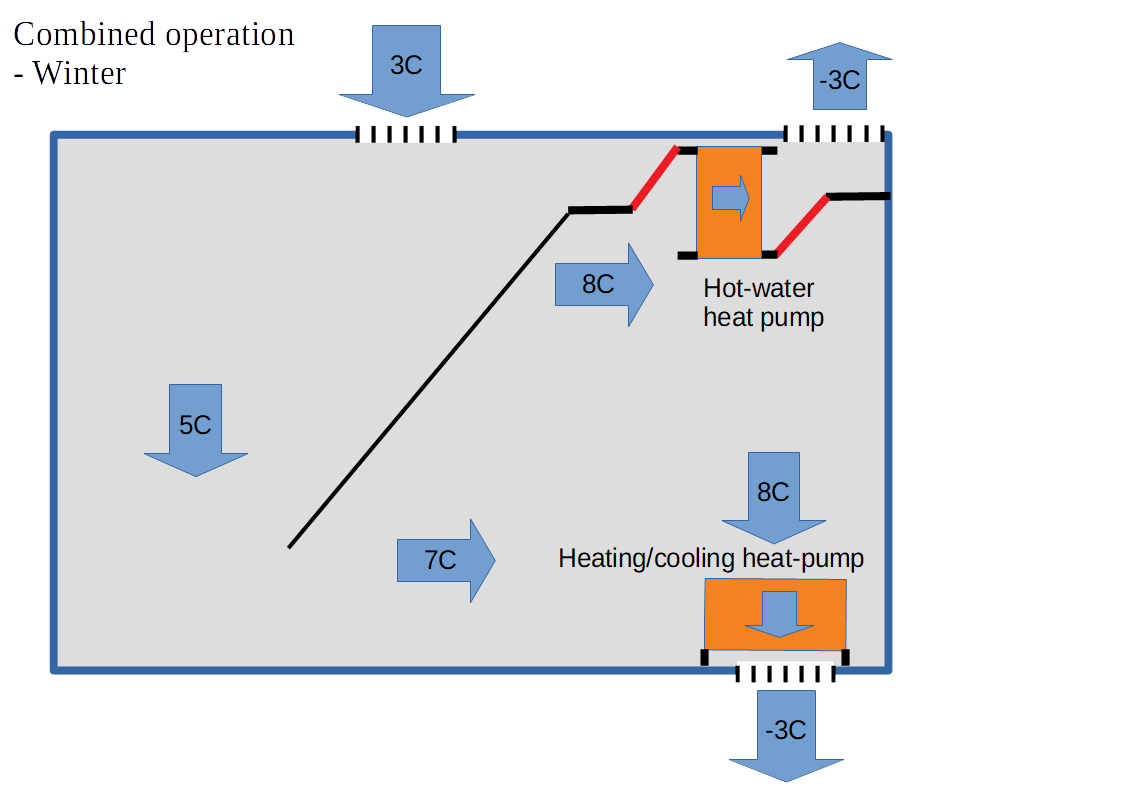

Sub-floor chambers + heat pumps. The air flow through a sub-floor chamber moderates the air temperature, but it’s not guaranteed to give air which is at the ideal temperature for indoor use. This especially so in winter. However the moderated air temperature can still be a benefit to a heat pump. The heat pump would need to be configured so that its discharge air passes to the outside without mixing underfloor.

Opening size. In this sub-floor chamber arrangement, air flow between outside and under the floor can only pass at two openings. These opening need to be at least as large as the area of the heat-pumps fan. If the openings are smaller then they will constrict the flow of air through the heat pump and reduce its performance.

Benefits. Positioning a heat pump under the floor might give a number of benefits if operated so that the air passes over the ground in a useful way:

- Efficiency. Moderating the air temperature at the heat pump inlet will usually, but not always, improve efficiency;

- Increased effectiveness. Improved efficiency makes a heat pump able to deliver more useful heating or cooling for a given level of input power;

- Reduced risk of icing. In winter, heat pump operation can sometimes be effected if ice that forms on the heat pump mechanism. All heat pumps are designed to cope with this. They have a special de-icing cycle during which there is no useful output from the heat pump. Moderated outside air will be less likely to give rise to icing in the heat pump;

- Increased high-temperature resilience. In a climate-changed future with extreme heat, the last thing we need is our cooling systems breaking down when it’s too hot. By moderating the inlet temperature, this sub-floor configuration makes heat pumps more resilient in the face of extreme heat;

- Aesthetic. Conventional heat pumps are normally positioned on the outside of homes in visible locations. By fitting the heat pump under the home, the visual impact can be reduced;

- Weather-resistant. Equipment which is fitted outside in the elements will invariably degrade more quickly than equipment which is sheltered. So fitting a heat pump under a floor may lessen weathering effects such as rusting of metal components, effects of wind-blown dust, and UV deterioration of plastic components;

- Security. Equipment located under the floor is more resistant to tampering and theft.

Disadvantages. Configuring a heat pump under a floor also has its potential problems:

- Access. Installation and maintenance of heat-pump equipment is made more difficult because access is likely to be constrained. This can be mitigated by careful design;

- Increased heat flow through the floor. The efficiency benefits are offset because drawing ambient air into the sub-floor space will increase the temperature difference either side (above and below) of the floor. This can be mitigated by having sufficient insulation on the underside of the flooring material;

- Costs. Compared with a conventional raised floor, configuring things to work in a useful way will require additional costs associated with preventing incidental air flow around the perimeter.

Add hot-water heat pump

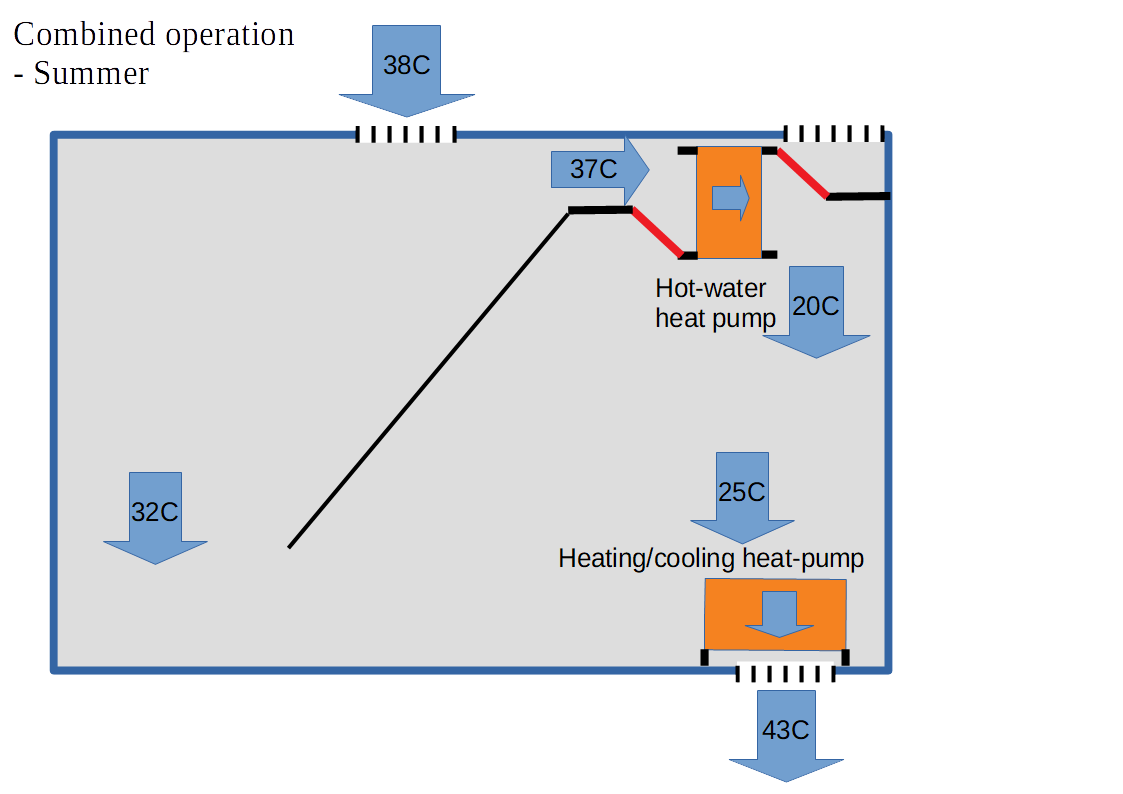

With respect to the ambient air source, a conventional reverse-cycle air conditioning unit has a heat pump that extracts heat in winter and adds heat in summer. However the situation changes if a hot-water heat pump is introduced, because it always extracts heat. So in summer, the discharged cool air from the hot-water heat pump is potentially valuable. It would be good to configure things so that we don’t throw away the beneficial cool air ejected from the hot-water heat pump. A possible configuration is shown below.

Sub-floor heat-pumps – aside

It’s worth noting that putting a heat pump underneath your floor is only beneficial if the discharged air from the heat pump doesn’t mix with the air drawn into the heat pump. The picture here was taken at a home where the heat pump will be working more poorly (relative to a conventional outside installation) because the discharged air exits to the right of the picture into a very confined space. That discharged air will then become turbulent and mix with the air being drawn into the heat pump at the left of the picture.