If you know a little about insulation then you’ll already know about R values. However, to really understand insulation you also need to know about U values and K values.

2018-07-29

By Richard Keech

Our comfort in our homes depends so much on that mostly unseen material – insulation. There’s more to insulation than meets the eye. I’ve written previously about insulation for ReNew magazine edition 127 “There’s a hole in the bucket, dear Liza: The benefits of insulation“. So take a look at that article as a starting point perhaps or just read on.

The story so far

Conduction. We know that insulation has an R value – the bigger the better. And the greater the R value the less heat that flows (all other things being equal). To be clear, R value is about resistance to heat conduction through a material (the term “R value” comes from ‘resistance’). Heat conducts through a material from hot to cold.

Temperature gradient. Think of that temperature difference across the material thickness as being like the height difference across a sloped surface. Heat flows down that temperature gradient like a marble rolls down an inclined plane. The greater the slope, the faster it goes.

Resistance adds in series. The next most fundamental thing about insulation value is that it adds when you stack it (ie in ‘series’). So two pieces of flat material, each with R value of 1, will give an R value of 2 if they are stacked one on the the other. So that’s twice the resistance to heat flow. Looked at another way, for a given type of material, R value is directly proportional to thickness (true so long as you ignore boundary effects for materials with very low R values – see the end of the article).

How much R? We most often think of insulation R values in the context of ceiling insulation. A good roof might have, for example, an R value of 5 or 6.

Be clear on U value

Maybe you’ve heard about U value being used in discussion about windows. U value is just another way of expressing the same thing as R value – from a different perspective. If R value is measure of resistance to heat flow, then U value is the inverse – the tendency to conduct heat flow. A piece of material with an R value of 2 can equally be expressed as having a U value of 1/2. So it’s a simple arithmetic inverse. Likewise, a U value of 5 is exactly equivalent to an R value of 1/5.

So R value and U value are both ways of expressing the same physical tendency, from a different point of view. Sometimes it makes more sense to use U values than R values. For windows it turns out that the range of values typically seen mean it makes more sense to use U values. For example, a single-glazed window might have a U value of 6. This makes for an easier-to-express value than the equivalent R value of 0.17.

How much heat flow? The rate that heat energy flows (which we’ll call Q) through a material is measured in watts. This is given simply as the U value, multiplied by the area (A) , multiplied by the temperature difference (dT) from one side to the other.

Q = U * A * dT

Example. If we have a large window with a U value of 6, an area of 5 square meters, and a temperature difference of 20 degrees Celcius between inside and outside, then the conducted heat flow is 6 * 5 * 20 = 600W.

Special K

What if we want to compare the tendencies of different types of materials to conduct heat? Perhaps we’re considering what makes a good insulation batt. Using R value or U value is no good. For this we need another measure because we could have two separate pieces of material with the same R (or U) value. But they’ll be of different thicknesses.

To compare one material against another we need to take thickness out of the equation. This is just like the difference between mass and density.

So we call the U value per unit of thickness the K value. K value is sometimes also express using the symbol ‘λ‘, the Greek letter lambda in lowercase.

K value then becomes the best way of looking at just how well different materials perform thermally. The smaller the K value the better.

K value is to U value what density is to mass.

The relationship is: D = K * R, or D = K / U where D is the material thickness.

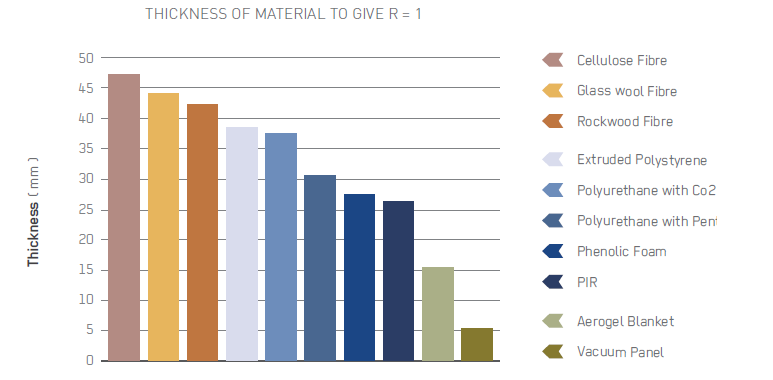

Another way of thinking about K value is that it expresses the thickness, in metres, required to give a U value of 1 (or R=1). For example, the K value of of polyester insulation batts is about 0.05. So that means ~50mm thick layer of polyester batting is needed for each R1 of insulation value.

(Figure credit: Alastair Leith from BZE Buildings Plan pp 65)

K values of some materials

VIP treatment. The material with the best (ie lowest) K value is vacuum-insulated panels (VIPs). As the name suggests, these are panels with a vacuum between the sides. A VIP has a K value of about 0.005 or 0.006 – so long as the vacuum is maintained. So a 20mm-thick VIP will have an R value of about 4. Looked at another way, this is about ten times the insulation value per unit thickness than polyester batting.

(Vacuum Insulated Panel – image credit: Proctor Group Australia)

Aerogel. Vacuums aside, the best performing insulation material is aerogel. This is an advanced and expensive silicon material. It has a K value of about 0.012. So 12mm thickness gives R1. Aerogel is rare and I’m yet to see it used in building.

(Spaceloft aerogel: image credit: Aerogels Australia)

Phenolic foam. A commonly seen high-performance insulation is phenolic foam boards such as Kingspan Kooltherm. This is a rigid foam material with a K value of about 0.020 – 0.025.

(Phenolic foam – image credit: Kingspan)

EPS. A more common insulation material is expanded polystyrene, aka EPS. This has a K value of about 0.040. So 40mm gives R1. An example is Fletchers Sisalboard.

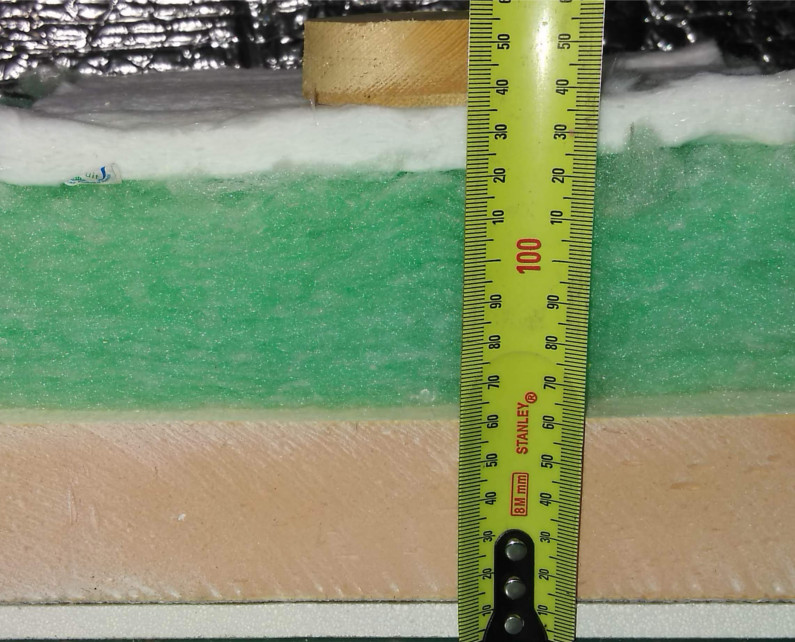

Glass Fibre Insulation. Everyone knows your basic glass-fibre batts. It is next in ranking of thermal performance. Its K value is about 0.050. This material is highly compressible, so it’s important to state that the K value diminishes if the material is squashed or otherwise not achieving its full height (‘loft’). So ideally, 50mm gives R1.

(Glass-fibre insulation: image credit: Knauf Insulation)

Polyester insulation. Insulation made of polyester such as Autex Greenstuff has a K value of about 0.050 – 0.060 (depending on the grade (density) and thickness). Lets call it 0.055. So R1 will be about 55mm thick.

Wood. Timber and insulation are often found together. For example in a stud-frame wall. So it’s useful to consider the relative thermal performance of the wood in comparison to the bulk insulation material. Pine has a K value of about 0.15 which means that a piece of 90mm framing timber has an R value of about 0.6 through its depth.

Plaster. 10mm of plasterboard adds about R0.06 [ICANZ Handbook Pt1] (excluding boundary-layer effects) which corresponds to a K value of 0.17.

Boundary-layer effects

A funny thing happens if you look at glass. For comparison, glass has a K value of about 1.0 – 1.1. So a 5mm-thick sheet of glass contributes only R 0.005. But we know a single-glazed window has a U value of about 6. Which is an R value of 0.17. How to reconcile that R 0.17 is 34x the theoretical R value of a sheet of glass (0.005) based on its K value.

It turns out that that nearly all the insulation value of a single-glazed window (excluding consideration of the frames) is the boundary layers of air on the surface of the glass. When dealing with good insulators the effect isn’t that noticeable. But it is important when thinking about thin layers and/or poor insulators.

The inside layer of air on a window contributes about R0.12 assuming still air. The outside later much less at about R0.04 because it’s air that’s much more freely moving [ICANZ Handbook Pt 1]. So over 95% of the little insulation value provided by a single 5mm layer of glass is actually from the boundary layers, not the material.

Boundary layer effects also help explain why pelmets are important for window coverings because they help retard the movement of air past the window.

For an internal horizontal inside layer (ie a ceiling), ICANZ reckon the boundary layer contributes R0.11.