2020-08-04

Richard Keech

Finding a builder

It’s mid 2019. Kate and I have a great home design, that’s got planning approval. Now it’s time to find someone to build our dream. From the outset the field is narrow because our design is intended to be a certified Passive House (PH). Our hope was to get two quotes and go from there.

We’d heard that another home to be built at The Cape is going to be PH, and built by North South Homes from Inverloch. I called them up and spoke to Wade Bashaw, the principal. Wade is an affable bloke who learned his trade in harsh climes of Canada. He has a passion for sustainable building in general, and PH in particular. He’s super keen to be involved.

The other builder we approached was Dave Martin from Martin Builders. Dave was already known to us, and had a great track record at The Cape already. Martin Builders is the construction arm of The Sociable Weaver group, which built the Ten-star home. Dave also featured in Grand Designs Australia, season 4, with the amazing Croft House near Inverloch. Dave, no doubt, was a highly skilled builder. However he had never undertaken a Passive House build before.

Along with our designer, Luke, Kate and I had a face-to-face meeting in Melbourne with each builder to size them up. Our initial impression was that Wade had the edge because of his track record with PH. However, Dave made the commitment that he would qualify as a Certified Passive House Tradesperson.

In August, we prepared a request for quotation, and issued it to both Wade and Dave. The RFQ included a detailed specification. The idea was to allow a direct apples-to-apples comparison of the responses. Despite the detailed spec, when the quotes came back, there were small differences in interpretation between the two builders. After adjusting the builders’ proposals/prices so that they reflected fair comparisons, there was a ~5% difference in price.

The winner is… Martin Builders was cheaper. On the other hand, North South had a really cool app-based system for providing regular and extensive feedback to clients which I really liked. Both had great reputations. We were confident that both builders’ proposals properly understood the challenges of the build and would both likely do a good job. So, ultimately it was on the basis of price alone that we chose Martin Builders.

Value management

Even though we’d chosen the best-value quote, the price was significantly outside our budget. So began the task of value management.

Roof construction. The biggest thing that changed in this process was the method of construction of the roof. The original design involved a vaulted ceiling with exposed beams in the main living area and the master bedroom. This ruled out the use of prefabricated trusses for the roof. In discussion with the builder and the designer, we settled on the use of a scissor-truss roof design for the main living area. We also dropped the vaulted ceiling in the bedroom entirely. We were happy that the scissor trusses would give the vaulted ceiling sufficient sense of volume to be in keeping with the original design, but in a way that was cheaper and quicker to build.

Winter deck. Two other non-trivial things were changed in the process of value management. First was the so-called winter deck. The original design concept involved two decks at the east end – the summer deck, in the shade, and the winter deck, positioned to the north east, which would give better access to the winter sun. For the sake of the budget, and with the notion that we could always add it later, we dropped the winter deck from the construction contract.

Garage. The other thing we changed was the garage, which was originally intended to be clad in timber like the house. We compromised and went for corrugated Colorbond cladding instead.

So, after a lot of back and forward, we arrived at a revised quotation that was acceptable. The saving in the process was about $120k.

Green roof

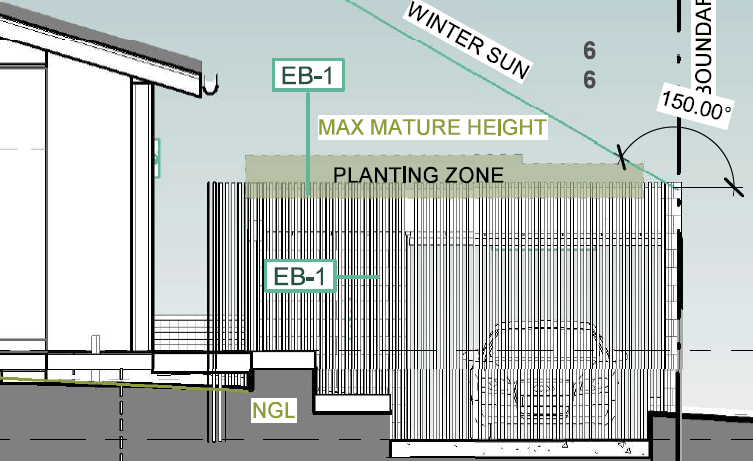

Since very early on in the design process, we had the idea that the garage roof would lend itself to a green (i.e. planted) roof. The positioning of the garage meant that the roof of it would be visible from the kitchen and the east deck. So, we imagined looking across a vegetated area, west to the horizon would make for a significant feature to the design.

I had previously met a fellow name John Hassall who, when I met him, worked for a small outfit called Do It On The Roof which specialised in green roofs and green walls. When I reached out to John for this project he was working freelance and trading as Greenly. John was immediately interested and was more than happy to give us a costed proposal for a green roof.

Eco Pillows. One of the challenges with a green roof is the structural implications arising from the extra all-up mass of the garden, including plants, soil, water, etc. To help with this John proposed a system called Eco Pillows. This was a light-weight, modular system for hosting the plants. It also has the benefit of allowing the planting to happen off-site. The planted-up Eco Pillow modules can have time to mature offsite, and be dropped quickly and easily into place onsite when ready. The nominal static structural wet load from the garden using the Eco Pillow system is 60kg/m2.

Roof and waterproofing. The other part of the green roof is the underlying roof material and waterproofing. Based on negotiation between us, the designer, and John, we decided that the garage roof would be made of plywood, which would then have a waterproofing layer. The builder would be responsible for the un-waterproofed roof, and John would be responsible for the waterproofing, as well as the supply and installation of the planted up roof and watering system.

The plantings were all intended to be low bushy plants or ground cover. The initial planting schedule was proposed as part of the first landscape design.

John gave us a costed proposal which was acceptable. The plan was that he would sub-contract the water proofing layer, and would supply and install the rest himself.

Windows

The design has specified high-performance tilt-and-turn windows and doors. In Pt 3, I indicated that the main contenders were:

- Ultimate Windows’ Legend series – UPVC, locally made from imported framing and mechanical system;

- Paarhammer – Timber frame, locally made with local timber and imported mechanical system;

- Logikhaus – Timber frame, made in Poland.

All three suppliers came recommended. I have previously visited the Paarhammer factory in Ballan (near Ballarat) and was very impressed.

For the timber-framed models, both came with the option of straight timber frame, or a timber frame with a powder-coated aluminium fascia. We liked the durability and look of the aluminium+timber.

The UPVC looked impressive and performed well by all accounts. However, I think the choice ultimately came down to a subjective one about the use of plastic window frames in a high-spec house. In other words, for the amount we were intending to spend all up on the construction, UPVC was probably going to feel like a compromise aesthetically.

So we got quotes for the timber-framed alternatives. Unfortunately the locally manufactured option was substantially more expensive. We would have loved to use a local supplier, and would have paid a bit more for the privilege.

Logikhaus ended up offering a top-end product with the best value for money.

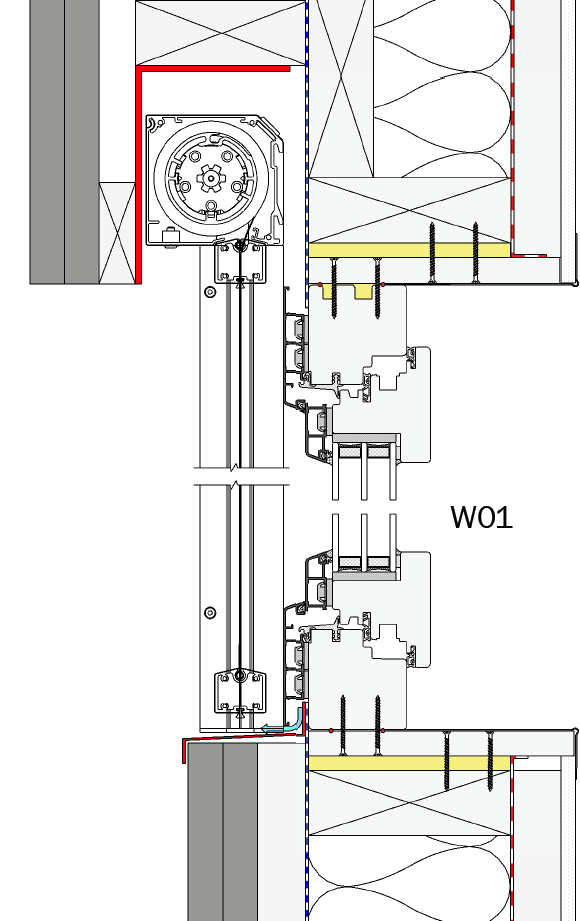

Details. The windows are all triple-glazed, argon-filled with low-e coating. They have frames made of finger-jointed pine and painted. The larger windows and doors have frames that are 88mm-thick (not including the Aluminium fascia). The rest are 68mm-thick. The biggest of the windows has three 8mm panes of glass. The U value of the individual window units ranges from 0.69 (largest window) to 0.90 (smallest window), depending on size, frame and configuration (average 0.79). The aluminium fascia elements have the optional welded, rather than mitred, corners. Sound reduction through the windows is an impressive 33dB.

Exterior zipscreen blinds. We also opted to get motorised exterior zipscreen blinds on the east- and west-facing windows. With the screens raised, the units will be hidden discretely within the cladding. The units are Nerli Zipner SQ90, provided by Logikhaus as part of the window order.

Dealings. Dealing with Harley and Jason at Logikhaus has been great. Their attention to detail is impressive. I particularly liked the installation tech drawings that Harley produced that show exactly how the window and blind will be installed in our particular context.

Bank loan

The less said the better. Suffice to say that getting a construction loan took much longer than expected. We came out of the experience chastened and bitter with our bank. We’d previously gotten two mortgage loans with Westpac. Both without a hitch. However this time, the process was a nightmare. The biggest problem seemed to arise from the scheduling of progress payments which were different to what they were used to. This mainly stemmed from the higher-than-usual cost of windows, plus the need for an up-front payment for the windows at the time of order. Banks are seemingly challenged by things that are a little different. We even tried a different bank. In the end, the other was even worse.

Star rating

Now we have the final construction drawings, the thermal rating can be issued. There being no significant changes since the preliminary design, the final official star rating comes in the same as the preliminary – i.e. 8.1 stars. Many of the assumptions in the thermal model were conservative. I’ve since modelled it at 8.6 stars.

Getting it over the line

From here to starting the build we need a signed construction contract and a building permit from a building surveyor. This all took a surprising amount of time. The back and forward finalising details in the construction contract was time consuming. We ended up signing the contract with Martin Builders on 20 December, hoping that construction could kick off early in the new year.

Permit. In the new year (2020), seems there’s still a bit to go. Getting the building permit proved a challenge. Having applied for the permit in November, the permit wasn’t issued till 4 March. The biggest hold ups were:

- Green roof. The building surveyor initially wanted rails on the green roof. We managed to convince them that it wasn’t going to be a trafficable surface;

- Shower screens. The design was originally for showers with no shower doors. Unfortunately, this got knocked back, so we had to modify the design to include shower doors.

Windows. Finalising the order for the windows also took some time. There was a lot of back and forward to get all the details of the order right. The order wasn’t placed till 10 March, which ends up becoming the critical path for the project because of the very long lead time. At the time the order is placed, delivery is expected late July.

So this leaves us ready for construction to commence.